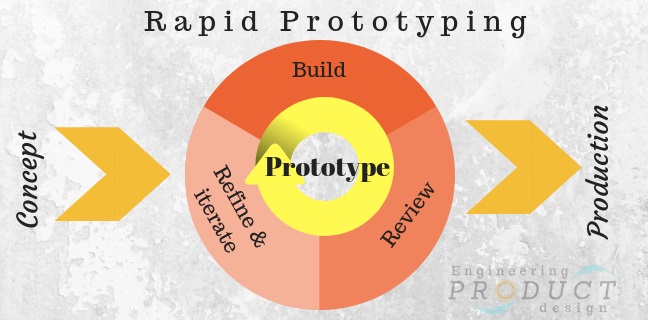

Fast prototyping measures include procedures used to make an item model with the guide of CAD programming. It is a significant interaction in assembling because of advantages like decrease of lead time, capacity to check mistakes, improvement of creation productivity, and so forth

There are numerous procedures utilized in fast prototyping. Normal machining methods incorporate CNC machining, infusion embellishment, and 3D printing. Picking the right strategy is anything but a clear cycle as a few components assume a colossal part in the dynamic. To make choosing the right strategy simpler, this article will examine three significant quick prototyping techniques and the variables that assume a colossal part in picking the right one.

Fast Prototyping Methods You Can Use?

Fast prototyping involves various cycles utilized in various situations. Along these lines, to know the right quick prototyping strategy to use, there is a need to know the various methods. The following is a clarification of the three normal fast prototyping techniques utilized in numerous enterprises.

CNC Machining

CNC machining is an assembling interaction that includes utilizing a PC program to arrange instruments and apparatus towards assembling an item. It is a subtractive assembling measure, i.e., the devices and apparatus, e.g., machines, processors, mill operators, and so forth, remove portions of the material.

The subtractive interaction depends on the CAD document previously transferred to the PC, and it chooses the end result. CNC machining is a famous fast prototyping strategy utilized in various businesses and situations.

Infusion Molding

Infusion forming is an assembling cycle that includes infusing liquid materials into an all around made shape. The liquid material cools downs and sets to shape the completed item. Infusion forming is a mainstream fast prototyping technique in businesses requiring large scale manufacturing of materials, e.g., plastic handling enterprises.

3D Printing

3D printing prototyping is another assembling interaction like the CNC prototyping machining measure since it depends on the utilization of CAD programming/documents. Nonetheless, not at all like CNC prototyping machining, it is an added substance fabricating measure. Rather than the product guiding the machines to remove, creation happens by setting down progressive layers of the material. These layers are a cut cross-segment of the item, and they can be changed as required. Thus, 3D printing is ideal for making complex states of items.

The Function Of Your Prototyping/The Purpose

The capacity of the model assumes an immense part in the fast prototyping technique to utilize. Quick prototyping is distinctive at each exceptional stage. There are four normal stages each with its highlights and thusly the suggested strategy:

Conversation of Design Ideas Stage

This is the primary stage, and it requires the utilization of an early model for the precise show of a plan thought. Since the early models are models and generally one, CNC machining and 3D printing are ideal quick prototyping strategies.

Conceptualization Stage

This stage expects you to explain the usefulness and type of the item. This incorporates getting the shape, size, and different diagrams of the item in the model. The right fast prototyping strategy relies more upon the materials and cost. 3D printing is the best technique. Be that as it may, if the material is metal, CNC machining is a superior decision.

Execution Stage

In this stage, the usefulness of the item will be tried. Hence, subtleties are vital. Since this stage requires different models because of the significant requirement for adjustment, infusion shaping is the most ideal decision. In any case, you can likewise utilize high-goal 3D printing.

Point by point Design Stage

Models fabricated at this stage are probable pre-creation confirmations. In case there is a requirement for variety, which is innate, infusion forming is the most viable technique.

Quality

The nature of the model you need decides the kind of fast prototyping technique for you. It shows whether you have accomplished the reason for prototyping. This is on the grounds that the model should be like the projected item.

You can make a bad quality model if your group esteems usefulness over appearance. It is a simple and practical approach to make a model, and creation is reachable by means of 3D printing or CNC machining.

You can likewise make a top notch model with an immense comparability to the projected item. This is significant when there is a need to test both usefulness and visual appearance. The two properties give the group and clients what’s in store with respect to how the projected item will function. Top notch models require high accuracy, low resilience, and so on, and this is attainable through CNC machining or infusion shaping.

Intricacy

The intricacy of the model likewise assumes a gigantic part in the kind of quick prototyping interaction to utilize. When managing complex parts that element empty plans, the best technique to utilize is 3D printing. In any case, while the strategy can create little complex parts, it very well may be costly when mass delivered. In such a situation, you may have to utilize infusion shaping.

Wanted Quantity

The ideal amount of models is another enormous factor to deal with while picking quick prototyping strategies. The best technique to use in large scale manufacturing is the infusion forming measure. Utilizing 3D Printing and CNC machining are just financially savvy for little amounts. Consequently, except if essential, added substance, and subtractive assembling strategies ought to be stayed away from in large scale manufacturing.

The Type of Material You Need

The sort of material your item and model are made of additionally assumes a gigantic part in picking the right quick prototyping technique. Both 3D Printing and CNC machining have a wide scope of viable materials. The following are a couple of materials viable with every method:

3D printing: Nylon, PLA, ABS, ASA, TPU, aluminum, treated steel, titanium, chrome-nickel-iron compounds

CNC machining: ABS, nylon, polycarbonate, PEEK, aluminum, treated steel, titanium, and metal

Infusion shaping: Plastic and nylon materials.

You can make an inferior quality model if your group esteems usefulness over appearance. It is a simple and efficient approach to make a model, and creation is reachable through 3D printing or CNC machining.

You can likewise make an excellent model with an immense likeness to the projected item. This is significant when there is a need to test both usefulness and visual appearance. The two properties give the group and clients what’s in store with respect to how the projected item will function. Excellent models require high accuracy, low resilience, and so on, and this is attainable by means of CNC machining or infusion forming.

Intricacy

The intricacy of the model likewise assumes a gigantic part in the kind of quick prototyping interaction to utilize. When managing complex parts that element empty plans, the best technique to utilize is 3D printing. Be that as it may, while the technique can create little complex parts, it very well may be costly when mass delivered. In such a situation, you may have to utilize infusion forming.

Wanted Quantity

The ideal amount of models is another gigantic factor to deal with while picking quick prototyping strategies. The best strategy to use in large scale manufacturing is the infusion forming measure. Utilizing 3D Printing and CNC machining are just savvy for little amounts. Accordingly, except if fundamental, added substance, and subtractive assembling techniques ought to be kept away from in large scale manufacturing.

The Type of Material You Need

The kind of material your item and model are made of likewise assumes a colossal part in picking the right quick prototyping strategy. Both 3D Printing and CNC machining have a wide scope of viable materials. The following are a couple of materials viable with every method:

3D printing: Nylon, PLA, ABS, ASA, TPU, aluminum, tempered steel, titanium, chrome-nickel-iron composites

CNC machining: ABS, nylon, polycarbonate, PEEK, aluminum, tempered steel, titanium, and metal

Infusion shaping: Plastic and nylon materials.